From the mechanization of labor during the first Industrial Revolution to the revolution of automation and data exchange, also known as Industry 4.0, manufacturing has been at the forefront of technological advancement. Today, the pace of innovation is accelerating, driven by digital transformation and interconnected systems that are transforming traditional manufacturing processes.

In this article, we will explore the cutting-edge technologies that are reshaping the manufacturing landscape and the impacts they have on businesses across the globe.

Table of Contents

Industry 4.0 and Smart Manufacturing

The Fourth Industrial Revolution, or Industry 4.0, represents a significant shift in the role of technology in manufacturing. At its core, Industry 4.0 is about creating “smart factories” where machines are augmented with web connectivity and data analytics to improve the manufacturing process.

Defining Smart Manufacturing

Smart Manufacturing is the overarching concept of an optimized, fully integrated, collaborative manufacturing system that responds in real time to meet the changing demands and conditions in the factory, in the supply network, and customer needs.

Key Components of Smart Manufacturing

This system relies on a fusion of production systems, IT, and digital technologies. At the center of this fusion are intelligent systems that are fully integrated throughout the entire manufacturing lifecycle.

Benefits for Manufacturers

The benefits of adopting smart manufacturing practices are many. Advantages include increased agility, real-time monitoring, predictive maintenance, and reduction in waste and defects, leading to improved product quality and customer satisfaction.

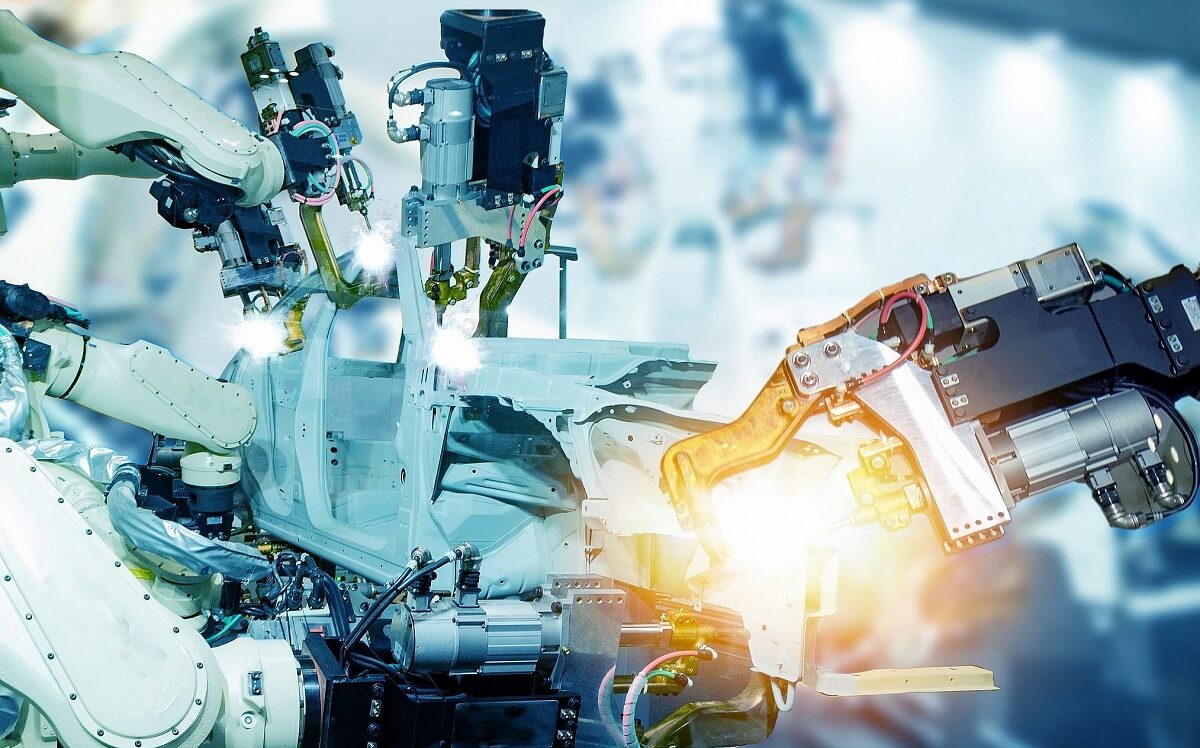

Robotics and Automation

One of the most apparent signs of the technological revolution in manufacturing is the rise of robotics and automation. Intelligent machines have been integrated into the manufacturing process, streamlining operations and increasing productivity.

Applications in Manufacturing

Robots have found their place in various manufacturing stages—from repetitive tasks to intricate processes such as assembly, packaging, and even quality control.

Impact on Efficiency and Productivity

The use of robots and automation has significantly reduced human error, enhanced precision, and radically increased the speed and consistency of manufacturing operations, leading to an overall improvement in efficiency and productivity.

Internet of Things (IoT) in Manufacturing

The Internet of Things (IoT) is at the heart of the Industry 4.0 revolution. In manufacturing, IoT refers to the network of physical devices embedded with sensors, software, and other technologies to connect and exchange data with other devices and systems over the Internet.

Connected Devices and Data Analytics

IoT devices can range from simple tools to complex machinery that provide a constant stream of data. This data can be processed and analyzed, providing manufacturers with insights that lead to better decision-making.

Enhancing Decision-Making Processes

The real-time data provided by IoT devices can be used to optimize production, pre-empt machine failures, and secure a more adaptable and agile production line that can quickly respond to changes in demand.

Additive Manufacturing (3D Printing)

Additive manufacturing, often referred to as 3D printing, is a process that creates a three-dimensional object by adding material layer by layer. This technology is disrupting traditional subtractive manufacturing processes.

Disruptive Potential in Traditional Manufacturing Processes

Although still in its early stages, the potential for 3D printing to revolutionize the manufacturing industry is vast. It is not only a complementary process to traditional manufacturing but also a complete transformation of how we think about creating products.

Challenges and Considerations

While the benefits of these technologies are clear, their adoption is not without challenges. To fully harness the potential of these innovations, manufacturers must address several key considerations.

Skills Gap and Workforce Training

The introduction of advanced technologies requires a workforce with new skills. Investing in the training and development of employees is crucial to the successful integration of these processes.

Cybersecurity Concerns

With the increased connectivity of devices, cybersecurity becomes a paramount concern. Manufacturers must ensure the integrity and security of their digital infrastructure.

Integration Complexities

The variety and complexity of the technology available can make it difficult to integrate systems seamlessly. Manufacturers need to carefully plan and execute their digital transformation strategies.

Future Trends

The future of manufacturing is set to be even more connected, automated, and data-driven. Looking ahead, several trends are emerging that will shape the landscape of production.

Predictions for the Future of Manufacturing Technology

Experts predict that advancements in artificial intelligence, machine learning, and further developments in 3D printing will continue to redefine what is possible in manufacturing.

Conclusion

The manufacturing industry stands on the cusp of a new era, one that is defined by the innovative use of technology. From smart factories to the mass customization made possible by additive manufacturing, the capabilities of modern production are expanding at an extraordinary rate. By understanding and leveraging these technologies, manufacturers can improve their competitive edge, drive efficiencies, and create a better, more sustainable future for the industry as a whole.